Change Language :

chainflex® creates space!

Smaller radii, smaller machines ... more possibilities

In line with current trends, modern machines are becoming ever smaller and more compact, so that smaller radii are being used more and more frequently in energy chains. The challenge now is to use cables that can withstand this additional load. Because, of course, customers still want their cables to work for a long time with high safety and reliability. Standard cables cannot do this reliably.What cables are suitable for small installation spaces? How can safety and a long service life be achieved? You can find answers to these questions, and other information, here.

No more space for good cable guidance in your machine?

In this video, we explain in a clear way how we solve the space problem. See for yourself!

Reduce installation space by up to 25% – motor cables

A motor cable is a comparatively simple cable. Its only task is to supply the motor with electricity. Because it is connected to a frequency converter, its voltage class is 600V/1000V, and it has four cores (L1, L2, L3, PE). Motor cables are used where large amounts of energy are transferred, but automation technology requirements have increased dramatically in recent years.

To meet all these requirements and stand up to the continuous mechanical load in an energy chain, materials and manufacturing processes are key to motor cable function. Ensuring reliable drive power supply under heavy loads remains an elementary task. A harbour crane is a good example.

igus motor cables are made with special high-quality networked XLPE insulation materials. They are specifically designed for energy chains and provide low capacitance for fast, low-loss switching times and a very high insulation temperature reserve with higher current density. They must also have a long service life when used in long travels or tight bends. Stranded wires in the cores must also be very high-quality in order to move the cable continuously in small installation spaces. This ensures a long service life and reliable power supply.

You can find more information about chainflex motor cables here.

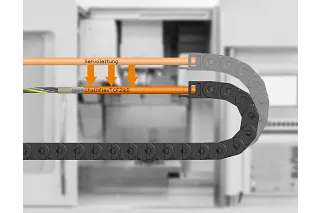

Reduce installation space by up to 32% – servo cables

Like a motor cable, a servo cable supplies the motor with power. We use the advantages of XLPE core insulation here, too, of course. But a servo cable also has other crucial functions: It supplies the motor brake with energy and/or carries the signal from the temperature sensor to the frequency converter. So a servo cable has one or two additional control pairs with additional shielding so that no interference reaches the frequency converter. Servo cables often also have an overall shield to prevent electronic magnetic interference because they then have better electromagnetic compatibility properties. A servo cable is therefore much more complex than a motor cable and also has many more cores. The additionally shielded control pairs mean that the cable is no longer as symmetrical as a motor cable, for example. This poses a particular challenge for the design of a high-quality cable.

The solution is the gusset-filling extruded inner jacket, which provides a firm foundation for the shielding and wraps around the additionally shielded control pair and guides the cores lengthwise. The inner jacket is especially important here, since it is the only way to achieve long core service life and guarantee durability for the high-quality shielding. Long travel distances and small bend radii put even more strain on the cable, so that special protection must be provided. A typical servo cable area of application is a storage and retrieval unit, but it is also indispensable for machine tools and handling linear robots.

You can find more information about chainflex servo cables here.

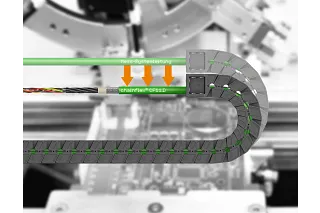

Reduce installation space by up to 32% – measuring system cables

Measuring system cables are often referred to as feedback or encoder cables. They are used for signal feedback from the transmitter system to the frequency converter. Information such as speed and angular position, which is important for correct drive use in automation technology, is transmitted at high density through various signal core combinations in the cable. This means a colourful mix of various cross section, core number, and shielding combinations that require special protection during movement. This is achieved with special pair shields or element jackets.

Long travels and small bend radii pose a special challenge, since that is where extreme forces act on the cable. The sensitive components in the cable make it important to use especially high-quality, selected materials in measuring system cable manufacture. High-quality materials such as TPE, a continuously gusset-filling extruded, robust inner jacket, a particularly closely woven shield with high coverage, and an optimal braid angle are essential components of a durable, fail-safe measurement system cable.They are especially important because measurement system cables are used wherever there is movement.

You can find more information about chainflex measuring system cables here.

Specialist articles on the subject of materials

You can download much more detailed information free of charge here

Consulting

I look forward to answering your questions

Shipping and consultation

In person:

Monday to Friday from 8:30am - 5.30 pm.

Online:

24h

WhatsApp-Service:

Monday - Friday: 8:30am - 5.30 pm.