Change Language :

Temperature-resistant cables

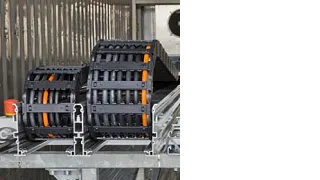

Heat-resistant cables are specially developed for use in extreme temperatures. There are cold-resistant cables and heat-resistant cables. Depending on the temperature spectrum, special chainflex solutions are used in these extreme areas. Temperature-resistant cables are preferred for applications that must continue to function in very hot or very cold ambient temperatures. The cables are used in a wide variety of industries, where there are numerous demanding application examples. For instance, low-temperature cables are often used in refrigeration and air conditioning technology or in the offshore sector, while high-temperature cables are frequently found in applications ranging from metallurgical, steel and rolling mill technology to cement, glass and ceramic processing. The function and reliability of the cable must be guaranteed in both hot and cold conditions, just as it is at normal ambient temperatures. Depending on the application, seasonal temperature fluctuations can also affect the jacket materials of the cables used outdoors. In the case of permanently moving cables, the mechanical load acts on the service life of the cable in addition to the adverse environmental influences. The company igus was the first to develop complete e-chain systems consisting of chainflex cable and e-chains from a single source for adverse conditions in the high and low temperature range.

Cold-resistant and heat-resistant cables

Tested in the test laboratory

In the igus test laboratory, all chainflex cables are tested in very complex test series. In addition to the 5,500m² test laboratory, igus® has set up a specially equipped large climatic container in which cables are tested in continuous motion at -40°C.

In their catalogues, all cable manufacturers specify two temperature ranges in which their cables can be used safely: one for fixed installations and one for moving applications. The reference to a binding standard is supposed to create comparability, but what is understood by the term "movement" in standardised tests does not have much to do with the actual movement in energy chains - especially with regard to the respective load.

For this reason, in addition to the tests in accordance with DIN specifications, we at igus have post-qualified all chainflex jacket materials offered with a wide variety of cables. By subjecting them to practical tests under real conditions in the igus climate-controlled containers. After almost 400 million strokes tested, we are therefore the only supplier able to provide three reliable categories: "fixed installation according to DIN", "moving according to DIN" and "e-chain according to igus test series under real conditions". This information creates security for our customers on the one hand and strengthens our guarantee on the other. We can only make guaranteed service life statements on the basis of these realistic test methods. The same principle also applies to the selection of the right bend radii.

Three categories of temperature resistance

igus test in the e-chain. In this test, the cable is assembled taking into account the bend radius, the interior separation and the strain relief. After installation, the cable is moved in accordance with the igus test standard values. The movement takes place in the climate container at temperatures down to -40°C. The test is deemed to have been passed if the structure is removed from the e-chain undamaged (in this particular case: without jacket damage). **Flexible:** Test according to DIN EN 60911-504 for "moved". The cable is cooled down to test temperature. After the cable has spent over 16 hours at the test temperature, it is wound onto a mandrel. After removal, a purely visual inspection is carried out. This so-called winding mandrel test is passed if the jacket of the cable remains undamaged. **Fixed:** Test according to DIN EN 50305 for "fixed installation". The cable is clamped at test temperature and loaded with a falling test weight. This so-called cold impact test is deemed to have been passed if the cable remains undamaged.

Fibre optic cable also tested for temperature resistance

How do chainflex fibre optic cables perform in extreme applications, e.g. -40°C?

Heat-resistant cable for minimal maintenance and high functional reliability

Wherever production involves great heat, a heat-resistant cable ensures safety. It is designed for extreme conditions and proves its worth in any area where heat resistance and flexibility are required, e.g. in energy chains for long travels.

igus offers highly developed plastic products for professional use. During development, it is of the highest importance that all products and systems work well together. Reliable operation even under high loads and a long service life are prerequisites for developments and new products to go into high-volume production. To ensure that a heat-resistant cable is fully functional over a long period of time, it is produced at igus via the chainflex® process. The material makes sure that the cable does not expand and contract when subjected to high or low temperatures, and signs of fatigue are prevented by the high flexibility. This high-quality jacket structure is complemented by the inside of the cable as the core, stranded wires and stranding are also motion-optimised.

Due to these valuable specifications, heat-resistant cables from igus are very popular where constant checks and maintenance work would prove difficult and result in high costs. Areas of application include the steel industry, plastics processing and also the construction of saunas. The heat-resistant cables from igus are the ideal partner for the igus tribo-filament, which can withstand temperatures of up to 180°C. However, a cable can only be as good as its accessories and supplementary parts. For a complete solution, we therefore also offer you plug connections, modular guide troughs and strain relief systems.

Consulting

I look forward to answering your questions

Shipping and consultation

In person:

Monday to Friday from 8:30am - 5.30 pm.

Online:

24h

WhatsApp-Service:

Monday - Friday: 8:30am - 5.30 pm.