Change Language :

Maintenance-free and lubrication-free knife edge rollers

White paper

Lubrication-free and maintenance-free knife edge rollers in the food industry

- Technology of knife edge rollers

- Benefits of our knife edge rollers

- Cost-benefit analysis

- Case studies and practical examples

Product white paper

In this product white paper you will find detailed information about our durable and wear-resistant knife edge rollers made of high-performance plastics. Write off for it now and get to know their advantages.

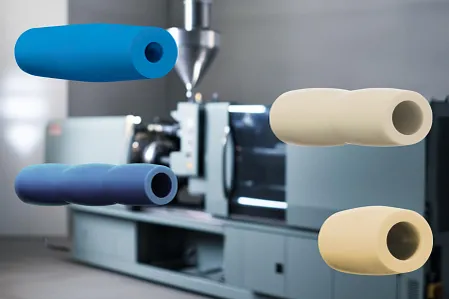

Injection moulding

You need customised rollers for knife edges in conveyor belts? We use injection moulding, precisely tailored to your application. Simply submit an enquiry without obligation and we will advise you on the choice of material and manufacturing process.

Bar stock

With our online CNC service, you can have knife edge rollers manufactured with customised lengths and shapes in just three steps. Use the tool to make an enquiry without obligation and find out the price at once.

Where are knife edge rollers already being used successfully?

Wear tests of various iglidur materials: results from the test laboratory

Consulting

I look forward to answering your questions

Shipping and consultation

In person:

Monday to Friday from 8:30am - 5.30 pm.

Online:

24h

WhatsApp-Service:

Monday - Friday: 8:30am - 5.30 pm.