Change Language :

Configured as required and harnessed ready for connection

Save time and space with an intelligent modular connector system

Step 1:

Select modules

Step 2:

Combine modules

Step 3:

Select housing

Step 4:

Combine housings

The customised interface

The Module Connect is the concept of a new type of plug-in connector for connecting electrical cables, fibre optic cables and pneumatic hoses. As a cable connector, our modular plug-in connector is characterised by a space-saving, flat housing and is used wherever several or even alarge number of cablesneed to be connected in the smallest possible space. The Module Connect won the{{anchor:null}}reddot design awardin 2018.

There's a lot in it for you ...

Get to know our Module Connect and its benefits so as to optimise existing applications, or include it when planning your next project.

Order your free personal consultation with sample box here. Our experts will introduce you to the product and show you individual ways in which you can benefit from using the Module Connect.

One connector module instead of many individual connectors

Thanks to the simple modular principle, an individual plug-in/disconnection point can be configured as a module from several connector housings. Each housing can be fitted with up to four different connector inserts.

The housings can then be joined together, allowing almost unlimited module variations in individual widths and heights. Thanks to the flat housing type, the Module Connect is very space-saving and enables a high contact density for every application.

Try it out at home or in the office and get a first impression

You can test the Module Connect with our new, free augmented reality service. Access the service with your PC and scan the QR code with your smart device for the AR model or click on the link directly with your smart device.

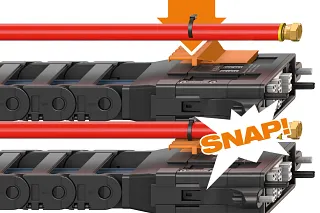

readychain® snap-on-carrier ...

... Expand your modular interface quickly & flexibly

Tech up:

- Simply attach other plug-in points directly to the interface

- All transfer points centralised in one place

Cost down:

- Click and fix

- Tool-free installation

Applications with Module Connect

Modular plug-in connector for energy chains

Connect your energy supply with just ONE connector

The connector modules can be adapted to the filling and geometry of the e-chain in one or more layers. This enables optimal cabling in terms of function and design for every application.

In combination with the universal strain relief from igus, secure fastening directly in the connector housing is possible. The soft elements used enclose the cable and hold it securely in place without damaging it. Visually modelled on honeycombs, the flexible structure adapts to different cable diameters, creating universal strain relief.

Our modular connector, also known as a quick connector, can be used in a variety of ways, for example at the chain's fixed end or moving end, between two energy chains or for inserting cables into terminal boxes or switch cabinets.

Adapter ensures easy and quick connection of the energy chain

The Module Connect adapter connects the Module Connect plug-in connector and the energy chain to form a coherent assembly.

- Saves up to 80% installation time

Connect to the machine in just a few simple steps - Clearly structured interface

Simple connection of the energy chain even without previous electronic knowledge - Sustainable

Existing igus energy supply systems can be easily supplemented - adapter is adapted to different e-chain series

More information

Consulting

I look forward to answering your questions

Shipping and consultation

In person:

Monday to Friday from 8:30am - 5.30 pm.

Online:

24h

WhatsApp-Service:

Monday - Friday: 8:30am - 5.30 pm.