Change Language :

Suitable for cleanrooms over long distances

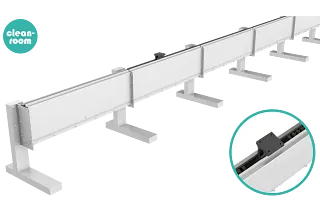

C6 energy chain series with cleanroom guide system

Innovative cleanroom solution for travels of up to 30m

The new version of the C6 cleanroom energy chain has a revolutionary guide system. It is compact and durable, enabling manufacturers to guide energy and data even on very long travels in production environments involving cleanrooms.

Tech up

- Innovative cleanroom solution with special guide, so that virtually no particles are produced even over long distances.

Cost down

- Secure power and data supply without further particle emissions on long transport distances in one system

Proof

- Complete system with 8m certified by Fraunhofer IPA with ISO Class 4, both with and without trough

Sustainability

- Higher production yield through particle reduction saves resources

Solution to the challenge of "long travels in cleanrooms"

Automated wafer transport in cleanrooms

In modern semiconductor factories, silicon wafers undergo numerous process steps - from lithography and etching to doping and metallisation. These processes take place in different facilities, which are often located far away from each other. Due to the strict requirements for cleanliness and freedom from particles, manual transport within the cleanroom is not feasible. A proven solution is the overhead hoist transport (OHT) - a rail-guided transport system that moves the FOUPs overhead and makes optimum use of cleanroom space. In addition to transport, storage in so-called stockers is also extremely important. These systems place high demands on the energy supply: the cables supplying the OHT units with power, and transmitting data must be reliably guided in dynamic and often cramped cleanroom environments - igus now offers an innovative new solution for this.

- Abrasion-resistant and ISO-certified by the Fraunhofer IPA

- Reliable on long travels

- Modular and low-maintenance - ideal for use in highly automated cleanroom environments

C6 energy chain series for cleanroom applications

Highest cleanroom suitability, hardly any abrasion, high stability

Abrasion resistance is the decisive parameter for energy chain applications in cleanrooms. The C6 energy chain series sets standards here. Abrasion is barely measurable. It could hardly be better: even under high loads, no abrasion can be measured on the new C6 cleanroom energy chain. Other advantages include extremely quiet running and easy assembly.

Tech up:

- Optimised design without measurable abrasion

- For ISO Cleanroom Class 1 applications

- High stability thanks to robust stop-dog system

- Smooth running due to moulded dampening element

- Side panels made of ESD material prevent static charging

You might also be interested in

Consulting

I look forward to answering your questions

Shipping and consultation

In person:

Monday to Friday from 8:30am - 5.30 pm.

Online:

24h

WhatsApp-Service:

Monday - Friday: 8:30am - 5.30 pm.