Change Language :

drylin R shaft guide - the maintenance-free solution

Guarantee robustness and precision

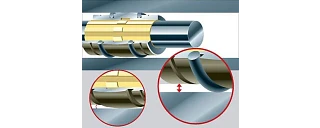

drylin R shaft guides are based on highly wear-resistant polymers developed especially for linear technology. The dimensions are compatible with standard ball bearings. The special shape of the shaft guides and shaft bearings guarantee toughness and precision - even under extreme environmental conditions.

You can find this on our website:

Why choose drylin R shaft guides?

One to one replacement very easy

Dimensions are identical to those of standard shaft guides with recirculating ball bearings

FDA compliance with stainless steel

Can also be used in the food and pharmaceutical industries thanks to special hygiene features

High precision

Adjustable bearing clearance at the sliding elements

Tough and flexible

Force absorption from all directions

Quiet operation

Low-vibration and quiet movement

Lubrication-free sliding elements push away dirt on the running surfaces of the shafts

The components of the drylin R shaft guide

Wooden shafts study

Wear on wood

We have carried out various tests on the coefficient of friction and the wear rate of our materials. Plain bearings and liners made of the materials iglidur J and J4 were tested on various wooden shafts in comparison to metal shafts.

Practical application examples for shaft guides

Commercial vehicle technology

drylin R transfers the steering movement from the front to the rear wheels.

To the article

Laboratory presses

The materials used here from the drylin R product range easily withstand the extreme conditions.

To the article

Wooden shafts in desks

A manually height-adjustable and tiltable wooden desk.

To the article

Track and tunnel cleaning

This tunnel cleaning vehicle required lubrication-free linear bearings with high rigidity.

To the articlesdrylin R linear guide

The advantages at a glance

- 100% lubrication-free

- Dimensionally identical to recirculating ball bearings

- Wide range of housing geometries

- Shafts, shaft end blocks and accessories available from stock

- 8 different shaft materials

- Interchangeable liners

- Housing available in VA stainless steel

drylin R shaft guide design

Floating bearings for shaft guides

The drylin R floating bearings offer great advantages in applications with parallel shafts. Due to their geometry, they are able to compensate for misalignment and parallelism errors and should be used on the shaft furthest from the drive mechanism.

| Properties | Characteristics of igus® plain bearings | Characteristics of rolling bearings | Technical data of igus® plain bearings | Technical data of rolling bearings | Particularly relevant for the following industries: |

|---|---|---|---|---|---|

| Precision | + | +++ | 0.02-0.15mm | 0.001-0.01mm | Machine tools, CNC processing, electronics manufacturing |

| Completely lubrication-free | +++ | + | Medicine, packaging, food, cleanroom, consumer goods | ||

| Maintenance-free | +++ | + | Industry-wide | ||

| Weight advantage | +++ | + | Aluminium approx. 2.7g/cm³ polymer approx. 1.5g/cm³ | Steel approx. 7.8g/cm³ | Handling, automation, laboratory, leisure time |

| High dynamics at low load | +++ | + | Packaging, handling, automation | ||

| High dynamics at high load | + | +++ | Packaging, handling, automation | ||

| Stroke length variance | +++ | ++ | Camera technology, textile | ||

| Coefficient of friction | + | +++ | 0.15 - 0.3µ | 0.001-0.05µ | Manual adjustment, swivelling |

| Sensitivity to dirt | +++ | + | Packaging, stone, textile, paper, painting systems | ||

| Noise reduction ¹ | +++ | ++ | 45-60dB | 60-70dB | Medicine, laboratory, furniture |

| Cost benefit | +++ | ++ | Industry-wide | ||

| Corrosion protection | ++ | + | Filling technology, chemicals, food | ||

| Magnetism | + | +++ | Plastic, aluminium | Steel | Medicine, test equipment |

| Chemical resistance | +++ | + | 1.4751 + iglidur® X | 1.4112 | Medicine, food, electroplating, filling systems |

| Compatibility of the assemblies | +++ | + | Jig construction, assembly line automation | ||

| Quiet operation without any vibration | +++ | ++ | Camera technology, inspection, medicine, 3D printer | ||

| Short-stroke suitability | +++ | + | Textile, handling | ||

| Easy to fit and quick replacement | +++ | + | Jig construction, assembly line automation | ||

| Stiffness | + | +++ | Machine tools, CNC processing, electronics manufacturing | ||

| Long travels over 10m | ++ | + | Camera, conveyor technology, material handling | ||

| Temperature-resistant | +++ | + | up to +250°C | Chemicals | |

| Smooth running | + | +++ | Manual adjustment | ||

| Acceleration, maximum ² | +++ | ++ | 50m/s² | 15m/s² | Automation, handling |

| Speed, maximum ² | +++ | + | 30m/s | 5-10m/s | Automation, handling |

- Measured in the igus® laboratory, 400 mm stroke, manual adjustment

- When subjected to low loads, depending on installation size 0.1 to 5 kg

Characteristics: +++ strong ++ average + weak

Consulting

I look forward to answering your questions

Shipping and consultation

In person:

Monday to Friday from 8:30am - 5.30 pm.

Online:

24h

WhatsApp-Service:

Monday - Friday: 8:30am - 5.30 pm.