Change Language :

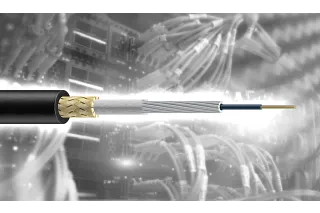

Fibre optic cable - flexible & resistant

Advantages of fibre optic cables

Structure of fibre optic cables

Our fibre optics section covers many different types of conductors. All cables are based on two types of fibre. One is the gradient glass fibre. The other is the glass fibre in a gel-filled cavity. The glass fibres are divided into OM (optical multimode) classes. These classes differ in transmission rate, referred to as Gigabit Ethernet. Our cables are of class OM2 or OM3, depending on type. They are also available in various fibre diameters, comparable to the cross-sections of copper cables. Our fibre optics have 50/125µ and 62.5/125µ for multimode fibres and 9/125µ for single-mode fibres. Multimode means that the fibre can transmit multiple light spectra. The single-mode fibre transmits only one light beam.

Fibre optic cables in small radii

Small radii are the greatest challenge in bus technology. Since the distance between the cores inevitably changes during movement, the capacity also changes, and transmission no longer works. But this is not the case with an optical fibre in the CFLG.LB cable. The distance between individual cores can change in movement without transmission losses. What is important is that few forces act on the actual fibre. We achieve this by using very short fibre strands in the cable and absorbing forces with special strain-relieving elements. This gives the cable and each fibre a strain-relieving braiding. The result is impressive. In our laboratory tests, we achieved 50 million double strokes in a bend radius of 35mm (factor 4.2 x d). Take a look at the test, and you will also discover many other highlights.

Areas of application for fibre optic cables

Fibre optic cables are used where they have advantages over copper conductors. These include production lines or cranes where signals have to be transmitted over a long distance. Industrial bus systems in particular quickly reach their limits when transmitting over long distances with a copper conductor. In contrast, transmitting the bus signal is effortless for the fibre optic cable. We offer a variety of fibre optic cables with a special jacket made of PVC, PUR or TPE. In addition, our cables have a perfectly matched structure with guaranteed service life in energy chain applications. Be it for special media resistance, high accelerations and speeds or simply resistance to oils and coolants.

Frequently asked questions

GOF & PCF fibres can only be harnessed in the field with enormous effort and equipment. As the sources of error, contamination, splice errors, etc., are very high, customers are usually advised not to do this. In addition, expensive special tools and expertise are required for assembly. With plastic fibres (POF), on the other hand, harnessing can also take place in the field under simple conditions and with simple tools.

Haven't found the right one yet?

Do you already know our online tool?

Easy to find, select the right type, calculate service life and order online

Product finder

Find exactly the right cable quickly

Service life calculator

Calculate the service life of any chainflex cable

Copper surcharge calculator

Calculate the daily copper surcharge

Configurator for customised cables

Configure your customised cable in just 3 minutes

Are you still looking for an energy chain for your cable?

Click here to go to the energy chain shop

... or everything already harnessed?

To the readychainConsulting

I look forward to answering your questions

Shipping and consultation

In person:

Monday to Friday from 8:30am - 5.30 pm.

Online:

24h

WhatsApp-Service:

Monday - Friday: 8:30am - 5.30 pm.