Change Language :

Linear axes with toothed belt drive

What you will find on this page:

Our toothed belt axes at a glance

Here you will find an overview of our product portfolio of linear axes with toothed belts. Whether with reverse, compact or as a modular system - you will find the right linear unit here.

Advantages of toothed belt axles

If you are looking for an axis for high speeds and dynamic movements, toothed belt axes are often the first choice. Here you can see the advantages of the linear drive with the aid of a toothed belt compared to other systems:

Structure of a toothed belt axis

A toothed belt axis is a versatile system that is used in various applications.Here you will find all the key elements that make up the structure of a toothed belt axis.

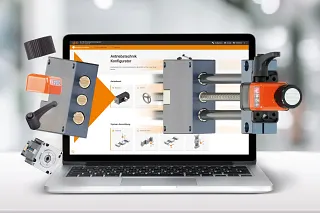

drive technology configurator

Customised toothed belt axes according to your wishes

With the online configurator for drive technology, you can enter your requirements and receive linear drives with spindle, toothed belt or rack and pinion drive, which you can configure according to your needs. Motors, motor controls and other accessories for your linear drives can also be ordered directly.

- Quick and easy configuration

- Optional accessories

- Detailed parts list

- Fast delivery*

Application examples with toothed belt axles

Free sample & white paper

Further information on toothed belt axles

Consulting

I look forward to answering your questions

Shipping and consultation

In person:

Monday to Friday from 8:30am - 5.30 pm.

Online:

24h

WhatsApp-Service:

Monday - Friday: 8:30am - 5.30 pm.