Change Language :

Sustainability measures of igus GmbH

As a company, we have a responsibility towards the environment and society. We see it as our duty to use resources sustainably and protect the environment. We do not interpret sustainability as a mere trend, but have made this aspect the focus of our business activities for several years, which characterises our business practices, products and partnerships.

Our goal: To achieve company-wide CO₂-neutrality by 2040 at the latest for all three scopes

At our Cologne site, we already operate our production and office space in a climate-neutral manner in accordance with Scope 1 (direct emissions) and Scope 2 (indirect emissions). We achieve this through the use of green electricity, green gas and energy-efficient measures in production and building technology. With our sustainability activities, we want to promote the success of our customers by delivering robust, sustainable and energy-efficient products that help them achieve their own sustainability goals. Our aim is to realise these efforts in a CO₂-neutral manner, including with regard to Scope 3 (indirect emissions in the supply chain), and without plastic waste.

Short term

Complete development of a company-wide carbon footprint with all three Scopes, based on the GHG Protocol by the end of 2025.

Reduction of Scope 1 and Scope 2 emissions across the company through renewable energies and energy efficiency measures.

Optimising our production processes to further improve our impact on the environment and climate.

Medium-term

Definition of an SBTi-compliant reduction target for Scope 3 and continuous reduction of emissions along the entire value chain.

Long-term

Achieving net zero emissions for all three scopes by 2040 at the latest through comprehensive measures and scientifically based compensation for remaining emissions.

Below we present our specific action plan for 2025, divided into the three Scopes 1, 2 and 3 - these measures only apply to our headquarters in Cologne, Germany. A plan for our international locations will follow in the course of this year. However, we would like to give you a brief insight into some of the resource-saving measures that we have implemented worldwide so far.

Measures to reduce Scope 1 emissions

Scope 1 refers to direct emissions, i.e. emissions that are caused directly by us as a company and are controlled by us. These include, for example, company vehicles, energy sources or coolants at the company site, combustion processes in production and our own heating systems for some of the igus buildings.

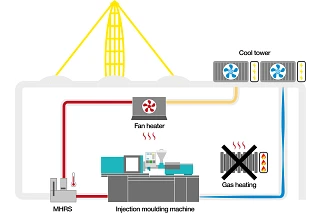

Utilisation of process waste heat through our own heating concept

In our injection moulding production, the machines have to be cooled via closed water circuits. This generates waste heat, which we now utilise to heat our production halls in winter. We have developed our own heating concept for this, the Machine Heat Recovery System (MHRS). This enables us to completely dispense with additional gas heating in some areas. We are currently working on rolling out the heating concept in our logistics centre.

Scope: 1

Savings potential: 83.56 tonnes of CO2 in the logistics centre (BAFA 2022 reference value)

Degree of implementation (actual status): 75%

Expansion of e-charging stations for company vehicles and employees

We have installed e-charging stations in almost all of our car parks, where our employees can charge their company vehicles as well as their own vehicles. We currently have 30 e-charging stations in operation, and the number is set to rise to over 40 in 2025. We are also currently building a multi-storey car park that will contain more charging stations.

Scope: 1 & 3

Degree of implementation (current status): 75%

Modernisation of existing buildings

We would like to gradually modernise our existing buildings and optimise their energy efficiency, e.g. by installing heat pumps. Possible buildings for sensible modernisation are being planned and some are already being implemented.

Scope: 1

Savings potential: 610 tonnes of CO2 equivalents per year (BAFA 2022 reference value)

Degree of implementation (current status): 10%

Measures to reduce Scope 2 emissions

Scope 2 includes indirect emissions from purchased energy, e.g. electricity, heat and steam, which we purchase from external suppliers and do not produce ourselves.

Optimisation of production processes through load profile reduction

After weekends and public holidays, we have to restart our large number of production machines. To ensure that the start-up is as energy-efficient as possible and that the power load profiles are kept even and low, we orientate ourselves on demand and situation-based switch-on plans.

Scope: 2

Savings: 400,000kWh of electricity

Degree of realisation (target status): 100%

Switch to renewable energies with 100% green electricity

Switching to renewable energy was one of our first major sustainability goals. In mid-2021, we switched all of our properties at the Cologne site to green electricity. However, we are also working on generating as much electricity as possible ourselves.

Scope: 2

Savings (compared to 2023): 13 tonnes of CO2 equivalents (BAFA 2022 reference value)

Degree of realisation (target status): 100%

Power generation through our own photovoltaic systems

In the course of the switch to renewable energies, we have already equipped various of our buildings with photovoltaic systems. The largest system currently has an output of almost 500kWp. Further buildings are being planned or realised. Our goal is to equip all igus buildings with PV systems, which would enable us to generate over 600,000kWh of electricity per year.

Scope: 2

Savings: 600,000kWh of electricity

Degree of realisation (current status): 25% (in relation to the possible total area)

Modernisation of LED lighting

We have installed almost exclusively LED lamps in all our buildings. The few remaining lamps are still being replaced occasionally and during operation.

We will also be installing an intelligent lighting concept within the production halls. Presence detectors and light incidence measurement systems detect the incident light from outside and dim the interior lighting accordingly.

Scope: 2

Savings: 380,000kWh of electricity

Degree of realisation (current status): 15%

Measures to reduce Scope 3 emissions

Scope 3 comprises indirect emissions in the supply chain. This includes all emissions that originate from external sources and are a consequence of our corporate activities. Examples include fuel consumption by employees travelling to work, by suppliers and when delivering products to customers. However, it also includes waste from day-to-day work and production as well as from products disposed of by customers.

Supporting the circular economy and covering the product life cycle with Chainge

The Chainge platform was created in 2022 from our recycling programme for the plastic energy chain, which was launched three years earlier. It is now possible to use the platform to recycle all products made from technical and industrial plastics and thus return them to the material cycle. Recyclates can also be bought and sold via the platform. Our goal for 2025 is to increase the collection rate by 30% and thus return 60 tonnes of plastic material to the cycle.

Scope: 3

Degree of realisation (actual status): 75%

Transparency through corporate sustainability reporting

In 2025, we will tackle corporate sustainability reporting (Corporate Sustainability Reporting Directive, CSRD). This should help us to obtain a complete and scientifically sound statement on all relevant CO2 emissions in our upstream and downstream supply and value chain. Our aim is to identify the hotspots of our Scope 3 emissions and then initiate further measures to reduce them.

Scope: 3

Savings potential: Not yet assessable

Degree of implementation (current status): 15%