Change Language :

Filling rules - cables and hoses in energy chains

General rules for cables and hoses in energy chains

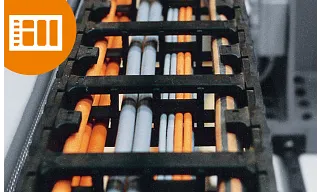

The key advantage of our energy chain systems is they can safely accommodate a wide variety of forms of data cables and energy suppliers in one system. You gave options of how to separate the different medias. For example, maintain minimum distances between bus and motor cables. You can mix pneumatics, electrical cables and hydraulics in the same compartments. In addition to the quality of the cables used, the arrangement of each cable within the energy chain and the space allowed are important for the system's service life. Various separation options allow energy chains to be adapted to the specific requirements of each application. This section provides detailed recommendations.

Contents

Maximum cable diameter

The maximum cable diameter corresponds to the clear height of the selected energy chain and energy pipes minus a clearance space. This minimum reserve is, for example, 10 % for electric round cables and 20 % for hydraulic hoses. An energy chain is ideally filled if a minimum lateral clearance to the next cable or to the wall is also left. Depending on the nature of the cable, the dynamics and the service life, more reserve must be provided. In exceptional cases, the filling can also be tighter. Please contact us about this.

Electrical cables require at least 10 % clearance space all round, hydraulic hoses 20 %.

The maximum cable diameter is specified for each energy chain series on the respective product page and in the respective catalogue chapter.

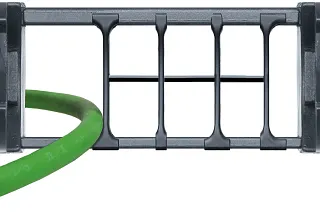

Instructions for energy chain interior separation

Cables and hoses with very different diameters should be laid separately. Separators are used for this. Cables and hoses must under no circumstances have the opportunity to tangle. Therefore, the clearance height of a compartment with several similar cables or hoses next to one another must not be more than one and a half times the cable/hose diameter.

The cable or hose weight should be symmetrically distributed along the width of the energy chain. Cables and hoses with different outer jacket materials must not be allowed to stick together. They may need to be laid separately.

Configure the interior separation of an energy chain quickly and easily online

- Simple handling

- Automatic filling of the energy chain with chainflex® cable or freely defined cable

- Avoidance of filling errors thanks to integrated set of rules

- Connection to our 3D CAD library

- Automatic creation of a parts list and drawing with dimensions

Filling rules

The cables must be laid and fastened in such a way that they can move freely in the longitudinal direction at all times and do not exert any tensile force on the energy chain in the radius. In applications with high travelling speeds and many load changes, cables must not be laid on top of each other without horizontal separation. The guide values for this are Travelling speed over 0.5 m/s and load changes over 10,000 p.a. The igus® interior separation offers a safe solution for this.

Bend radius R

Your energy chain's bend radius depends on the thickest or stiffest cable or hose in your filling. The bend radii should be adjusted to the recommendations of the cable or hose manufacturer. Selecting a larger radius than the minimum will extend service life. The specification of minimum bend radii for cables and hoses refers to normal temperatures. Other bend radii may be recommended.

Filling rules | Electric round cable

For electric cables, the round cable is a safe, modular and cost-effective solution for energy chain systems.

Filling rules | Pneumatic hoses

Filling rules | Flat cables

Filling rules | Hydraulic hoses

Strain relief

Hydraulic hoses are most often stretched lengthwise during operation. This must be taken into account when strain relief is applied. More hose length can be factored in or strain relief implemented. In some cases, one-sided strain relief on the moving end can be tolerated.

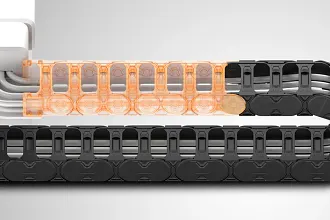

Rollclip

In almost all cases, the broad, smooth, rounded contact surfaces of all igus energy chains/energy tubes are sufficient to protect hydraulic hoses from abrasion. In extreme cases, the rollclip can be subsequently installed. In the crossbar, the hoses come into contact with a series of plastic cylinders which rotate with them. Extreme cases include particularly soft jacket materials, particularly small bend radii, and highly dynamic loads. Our experience shows that over 95% of all applications can be solved without rollclips.

Configure the interior separation of an energy chain quickly and easily online

- Simple handling

- Automatic filling of the energy chain with chainflex® cable or freely defined cable

- Avoidance of filling errors thanks to integrated set of rules

- Connection to our 3D CAD library

- Automatic creation of a parts list and drawing with dimensions

More information

Energy chain Shop

With over 100,000 products: From small, medium and large energy chains to customised solutions.

Knowledge Base energy chain

Find all the most important information as well as questions and answers about energy chain.

Online seminar

Benefit from the knowledge and experience of our speakers.

Blog: energy supply

Find interesting parts about energy supply in our blog.

Consulting

I look forward to answering your questions

Shipping and consultation

In person:

Monday to Friday from 8:30am - 5.30 pm.

Online:

24h

WhatsApp-Service:

Monday - Friday: 8:30am - 5.30 pm.